Quality Control

Blueprint's Quality Statement

“Quality is MY responsibility. 100% conforming parts to our customers.”

Every member of our team embodies this principle. This statement is carefully crafted to ensure that all team members understand their responsibility for the quality of every part that leaves our facility, as well as the quality of our interactions with customers, vendors, and community members. Quality is at the core of everything we do.

Industry-Leading Quality Control for Consistent Results

At Blueprint Advanced Manufacturing, quality control is integrated into every aspect of the business, from RFQ to shipping and everything in between. Our ISO 9001-certified facility uses advanced inspection equipment to guarantee every part meets your precise specifications. From first article inspection to final PPAP reports, we ensure accuracy, consistency, and reliability in every component.

Our Quality Control Capabilities Include:

- ISO 9001 Certification: Ensures rigorous quality management throughout production.

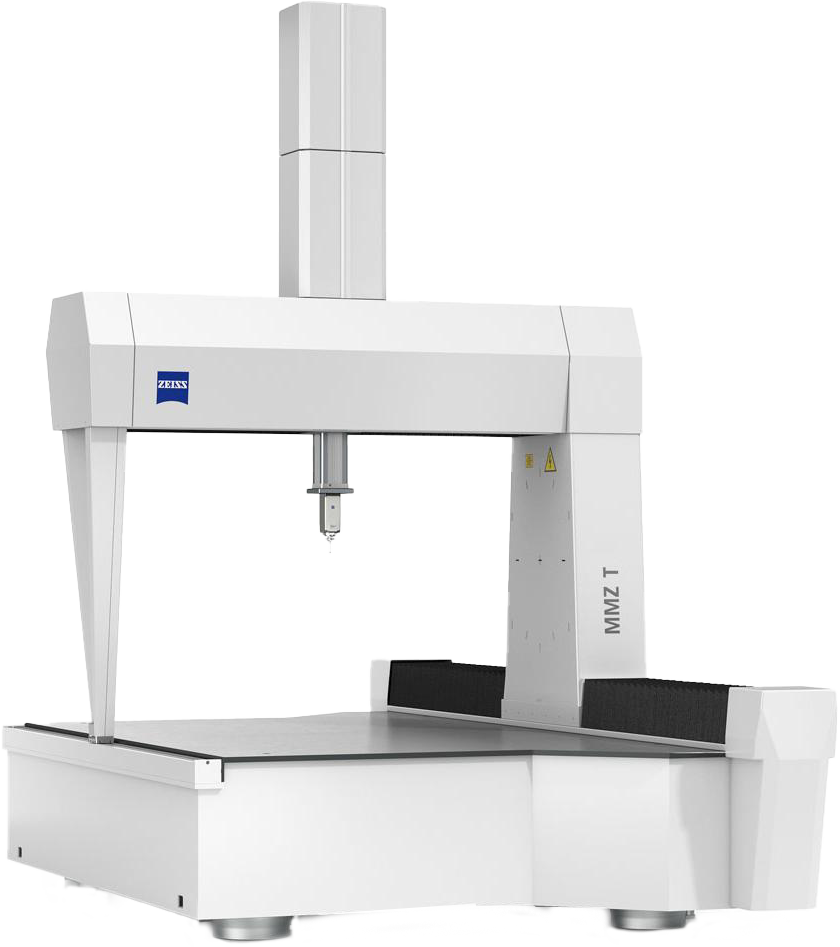

- Zeiss Automated CMM: With 5-axis probe for high-precision, lights-out inspection.

- Brown & Sharpe Manual CMM: Real-time, on-floor inspections performed by machinist-trained staff.

- Fowler Sylvac Scan F60T: For optical and dimensional inspection.

- Metrology Tools & Instruments: Comprehensive catalog of instruments, including gauge pins, thread gauges, air gauges, indicators, micrometers, calipers, and optical comparators.

- 1st Article, Final, and PPAP Inspection Reports: Comprehensive reporting available upon request.

Materials We Work With

We apply our rigorous quality control processes across all materials to ensure precision and reliability for every part.

Advanced Metrology for Precision Inspection

We use the latest inspection technology to ensure precision for every part, guaranteeing that components meet the tightest tolerances and specifications.

Key Equipment

Zeiss Automated CMM

5-axis probe for lights-out operation and high-precision inspection.

Brown & Sharpe Manual CMM

Machinists trained for on-the-floor, real-time inspections.

Fowler Sylvac Scan F60T

Optical and dimensional inspection for detailed accuracy.

Acurite Absolute Zero Optical Comparator

Ensuring geometric accuracy for complex parts.

See Quality Control In action

The Fowler Sylvac Scan 460T is able to scan 46 features in less than 40 seconds with 0.0001″ accuracy.

Our Digital Ecosystem

Blueprint integrates administrative, operational, and quality functions across the board. The core enabler of this synergy is our robust digital ecosystem—a suite of interconnected tools, platforms, and workflows designed to optimize efficiency and foster collaboration across all levels of the organization.

Key Softwares

ProShop ERP

Proshop is a digital manufacturing ecosystem that is the backbone of our business and software platform. “It touches every aspect of our business and therefore allows every member of our team to know what needs to get done, how it needs to get done, and when it needs to be done.”

Why Partner with Blueprint Advanced Manufacturing for Quality Assurance?

Blueprint Advanced Manufacturing’s commitment to quality extends beyond production. We maintain the highest standards of accuracy, reliability, and traceability in every part we produce. Our advanced inspection processes, paired with skilled technicians, guarantee that every component meets your specifications, from start to finish.

Key Points

Quality department staffed with mechanical engineers.

- ISO 9001 certification ensures consistency and quality at every stage.

- Advanced CMMs for high-precision, automated inspections.

- Comprehensive inspection reports and PPAP documentation available.

- Skilled team trained in real-time, on-floor inspection techniques.

- Proven track record of delivering parts that meet the most stringent quality requirements.

Need precision you can rely on?

Contact us today to learn more about our quality control services and request a quote.