Machining

Precision Machining for Complex Geometries and High-Tolerance Parts

At Blueprint Advanced Manufacturing, our machining capabilities deliver exceptional precision for complex components across a wide range of sizes and materials.

State-of-the-Art Machining for Your Most Demanding Projects

At Blueprint Advanced Manufacturing, we specialize in high-precision machining that meets the exacting standards of modern industries. From intricate milling to high-tolerance turning, our machining services offer consistent, reliable results for both small and large-scale projects. Whether your components require multi-axis milling or continuous production with turning, we guarantee precision, efficiency, and on-time delivery.

Key Machining Capabilities

- Milling Capabilities: Full 4th axis capable, handling workpieces up to 50 inches long and 20 inches wide.

- Turning Capabilities: Diameter range from 1/8” to 15”, with automated bar feeders and sub-spindles for continuous production.

- High-Pressure Coolant Pumps: For deep-hole drilling and enhanced part quality.

- Live Tooling & Multi-Operation Machining: Reduces lead times by combining processes in a single setup.

- Lights-Out Operation: Ensures cost-effective production with machining for both turning and milling operations.

Materials We Work With

We specialize in machining a wide range of materials, from standard metals like stainless steel and aluminum to more challenging exotic alloys, ensuring precision for all part complexities.

Advanced Machines for Precision Machining

Our machining capabilities are powered by cutting-edge technology, enabling us to handle both simple and complex parts with high accuracy and repeatability.

Key Equipment

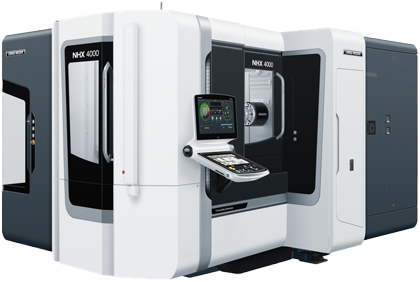

Mori Seiki NHX4000

Full 4-axis high-speed machining with a 5-pallet system for multi-part production.

Mori Seiki DuraVertical

Versatile machines for detailed precision milling.

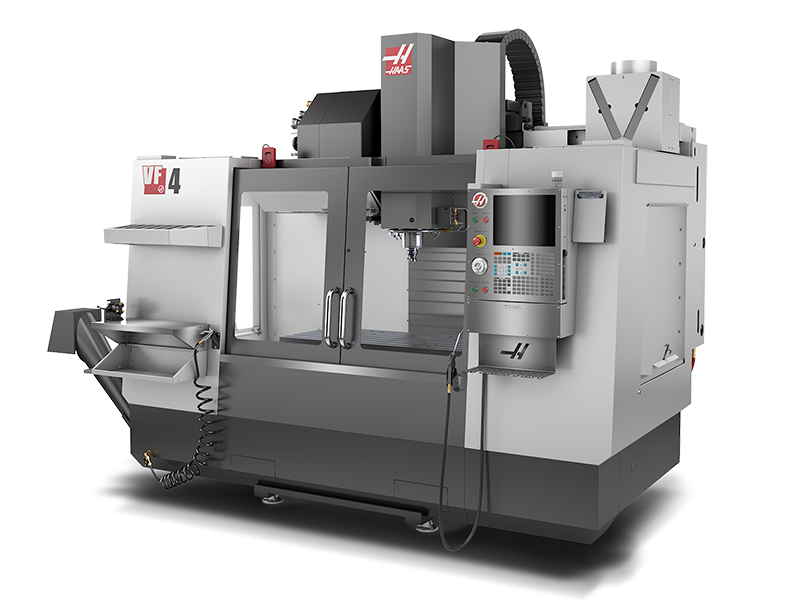

Haas VF 4/VF 3 with Pallet Systems

Flexibility and automation for various production needs.

Okuma Captain L470/LU4000 Simulturn

Heavy-duty turning for larger components.

Mori Seiki NLX2500SY/NLX2000SY

Sub-spindles and live tooling for multi-operation machining. Equipped with bar feeders, parts catchers, gantry arms, and parts carousels to facilitate efficient production.

Tsugami MO9SY

High-precision turning for small, intricate parts.

Why Partner with Blueprint Advanced Manufacturing?

With a focus on precision, innovation, and reliability, Blueprint Advanced Manufacturing is your trusted partner for all machining needs. Our commitment to quality and investment in technology allows us to deliver exceptional results on time and within budget.

What Sets Blueprint Apart?

- 300+ years of combined manufacturing experience

- Industry-leading equipment for high-precision milling and turning.

- Skilled machinists dedicated to quality and precision.

- ISO 9001 certification ensures consistency and quality control.

- Ability to handle both small-scale prototypes and large-volume production.

- Expertise in working with a wide range of materials, including exotic metals.

Ready to experience precision machining with Blueprint Advanced Manufacturing?

Contact us today to discuss your project and receive a quote.