Precision Manufacturing Capabilities Tailored to Your Needs

At Blueprint Advanced Manufacturing, precision is at the core of everything we do. From intricate milling operations to high-tolerance turning and rigorous quality control, our team ensures each part is made to exact specifications. Explore our full range of capabilities below, where each specialty is backed by decades of experience and advanced technology.

Milling

Our milling services utilize full 4th axis machining to create complex components with superior accuracy. With capabilities up to 50 inches in length and 20 inches wide, we can handle both small- and large-scale projects. High-pressure coolant pumps enable deep-hole drilling, while advanced tooling ensures the highest-quality cuts, even with exotic metals.

Key Milling Equipment

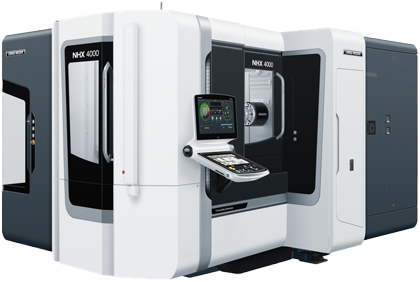

Mori Seiki NHX4000

Full 4-axis high-speed with a 5-pallet system for dynamic production manufacturing with lights-out capabilities.

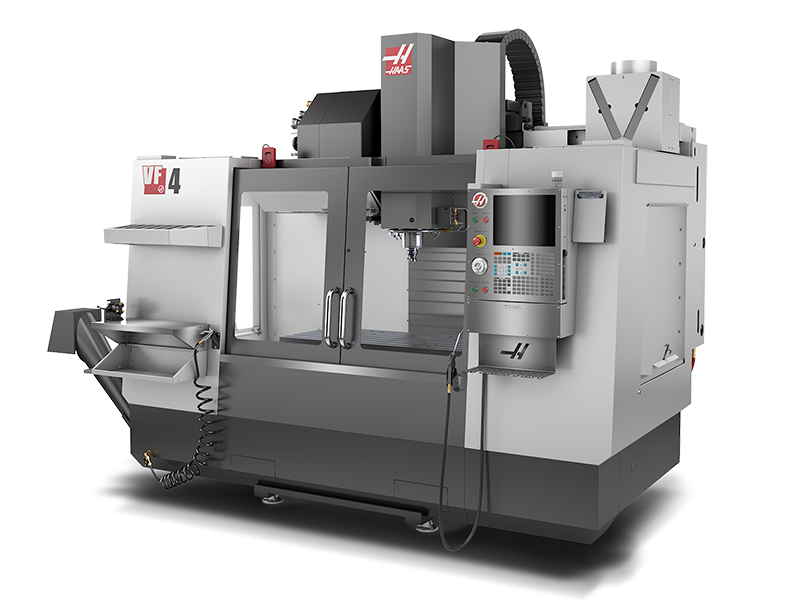

Haas VF 4/VF 3 with Pallet Systems

Flexibility and automation for various production needs.

Mori Seiki Duravertical

High-performance vertical machining capabilities with precision engineering

Turning

Our turning capabilities range from 1/8” to 15” diameters, allowing us to accommodate a wide range of parts and materials. Automated bar feeders, sub-spindles, live tooling, and lights-out operations ensure maximum efficiency, while advanced tail stocks support high-precision shaft work. Whether it’s a prototype or full-scale production, our turning department is equipped to meet your most demanding needs.

Key Turning Equipment

Okuma Captain L470/LU4000 Simulturn

Heavy-duty turning for larger components.

Mori Seiki NLX2500SY/NLX2000SY

Sub-spindles and live tooling for multi-operation machining.

Tsugami MO9SY

High-precision turning for small, intricate parts.

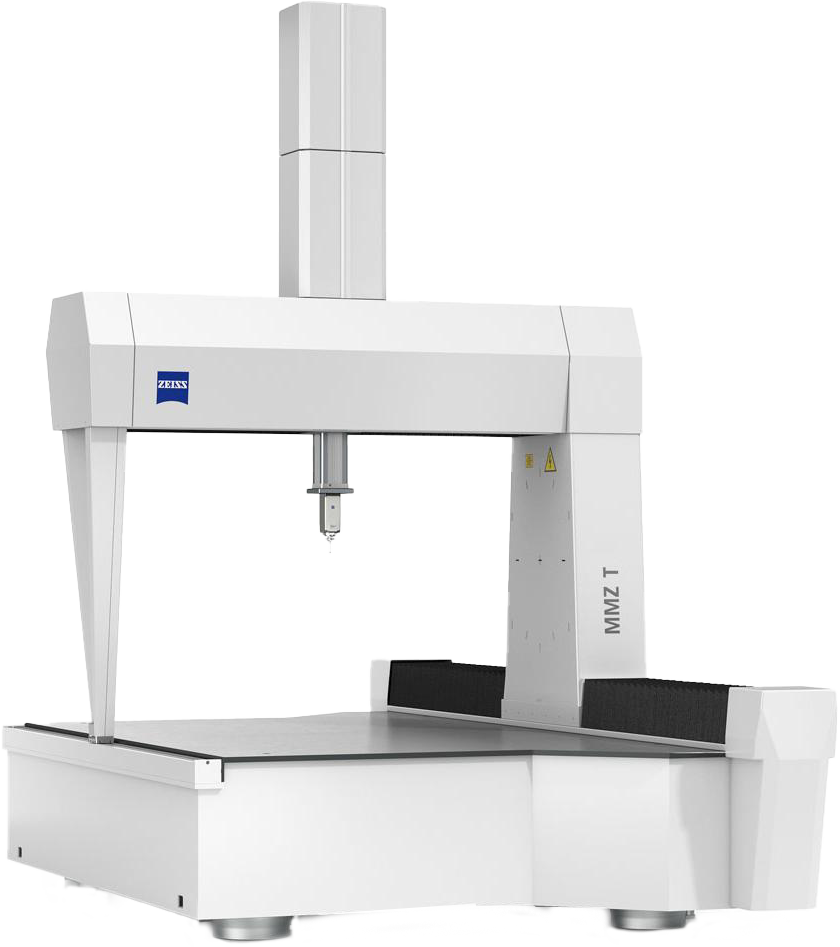

Quality Control

Our ISO 9001-certified facility maintains rigorous quality control processes to ensure every part meets your specifications. We use advanced inspection tools, including the Zeiss Automated CMM with a 5-axis probe for high-precision inspection, allowing us to guarantee parts are checked at every stage. Additionally, all our machinists are CMM trained to ensure consistent quality from production to final inspection.

Key Quality control Equipment

Zeiss Automated CMM

5-axis probe for lights-out operation and high-precision inspection.

Brown & Sharpe Manual CMM

Machinists trained for on-the-floor, real-time inspections.

Fowler Sylvac Scan F60T

Optical and dimensional inspection for detailed accuracy.

Additional Capabilities

Beyond our core machining capabilities, Blueprint provides an extensive array of supplementary services to fulfill all your project requirements. Our offerings include laser engraving, sawing, bead blasting, anodizing, and heat treating, ensuring your parts are finished to precise specifications. With our in-house finishing services and reliable local partners, we guarantee meticulous attention to detail, right down to the final touch.

Capabilities Overview

Sawing

Precision cutting with the Amada Dynasaw 430 for accuracy. It is able to accommodate bar stock up to 15″ in diameter.

Finishing

Services include bead blasting, honing, grinding, plating, anodizing, and powder coating for the perfect finish.

Laser Engraving

For precise and durable part markings.

Surface Grinding

Okamoto 6-18 Dx Surface Grinder for detailed surface finishing.

Honing & Tumbling

Sunnen Hone Machine and Mr. Deburr Tumbler for part cleaning and preparation.

Unmatched Precision

No matter the complexity of your project, our diverse capabilities ensure we can handle every aspect with care and expertise. Ready to get started?”