Secondary Operations

Secondary Operations for a Perfect Finish

Our comprehensive secondary operations provide the finishing touches your components need for superior durability, appearance, and performance.

Comprehensive Finishing and Processing Services

Beyond our core machining capabilities, Blueprint provides an extensive array of supplementary services to fulfill all your project requirements. Our offerings include laser engraving, sawing, bead blasting, anodizing, and heat treating, ensuring your parts are finished to precise specifications. With our in-house finishing services and reliable local partners, we guarantee meticulous attention to detail, right down to the final touch.

Our Secondary Operations Include:

- Sawing: Precision cutting with the Amada Dynasaw 430 for accuracy. It is able to accommodate bar stock up to 15″ in diameter.

- Laser Engraving: High-precision laser engraving for part identification, logos, or barcoding.

- Bead Blasting: In house bead blasting for smooth, clean finishes.

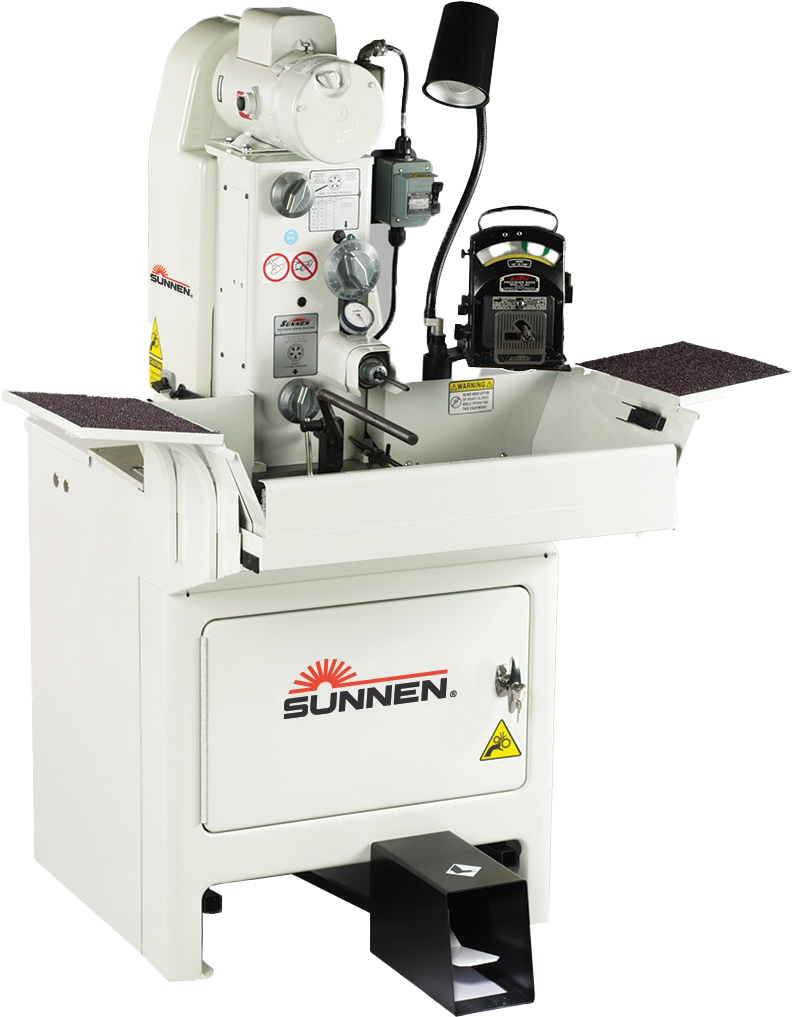

- Honing & Tumbling: Sunnen Hone Machine for accurate internal finishes and polished edges.

- Assembly: Skilled assembly services to ensure all components are securely and precisely integrated for optimal performance.

- Finishing: We partner with trusted vendors with stellar reputations in the manufacturing community for heat treating, powder coating, and various plating processes, including anodizing, Chromate conversion coating, Electroless nickel, zinc, passivation, and much more.

Materials We Work With

We provide finishing services across a range of materials, ensuring every part meets performance, aesthetic, and functional standards.

State-of-the-Art Equipment for Precision Finishing

Our secondary operations are powered by high-precision equipment to ensure superior finishes and lasting quality for every component.

Key Equipment

Amada Dynasaw 430

Precision cutting with the Amada Dynasaw 430 for accuracy. It is able to accommodate bar stock up to 15″ in diameter.

Empire Bead Blast Cabinet Pro Finish EB-3648

Bead blasting for smooth, clean finishes.

Clemco Zero BNP Blast Cabinet

Efficient, precise surface preparation.

Sunnen Hone Machine MBB-1660

Ensures precise internal finishes.

Okamoto 6-18 Dx Surface Grinder

High-precision grinding for smooth surface finishes.

Why Partner with Blueprint Advanced Manufacturing for Finishing?

With our comprehensive range of secondary operations, we ensure that every part is delivered to your exact specifications—fully finished, inspected, and ready for use. We combine in-house expertise with trusted local vendors to deliver the highest quality results for your project.

Key Points

- Expertise in a wide range of finishing processes, from sawing to laser engraving.

- Advanced equipment for precision and consistency in every operation.

- Trusted local partners for outsourced finishing services.

- Proven ability to meet exacting customer specifications for appearance, durability, and performance.

Need finishing services to complete your components?

Contact us today to learn more about our secondary operations and get a quote.